Safety first!

FOPS cabin protection

ECHLE FOPS cabin protectors are available in different versions. In addition to the patented, retractable cab protection structure, folding versions or polycarbonate FOPS are also available. The FOPS anti-splinter screen offers a special function: with this cab guard, the anti-splinter screen can be lowered at the touch of a button.

You can also find a large selection of cabin protection variants in our online store at echle-shop.com, further product information can be found in the product flyers under Downloads.

NEW: PROTECTOR E4

With the PROTECTOR E4, the most promising generation of FOPS protective structures has now been created. The advantages are more than convincing: the basis of every guard is safety, which in the case of the patented PROTECTOR E4 has been tested and certified to ISO 10262 category 2. The grille is fitted to existing screw-on points on the cab and can therefore be installed without any additional preparation or great effort. A hinged grille on the roof allows unrestricted cleaning of the roof window, which provides more light in the cab.

However, this is not the only innovation that has a positive effect on visibility: each individual grille bar is aligned in the direction of vision, allowing optimum all-round visibility. By customising the shape of the protective structure to each cabin, the installation height of the PROTECTOR E4 can be reduced to a minimum of 40 mm. Where previously strength and skill were required, gas struts now ensure effortless and assisted swivelling of the front guard from the ground or the cab.

Retractable FOPS

The retractable FOPS (type-tested and certified to ISO 10262 category 2) offers the highest safety standard for working with excavators. This protects the cab and thus the machine operator from falling rocks and other hazards. The European patent for the Frontguard insertion system developed by ECHLE is registered under EP13156559.0.

The slide-in canopy guard has a short, firmly bolted lower front guard section, an upper front guard section that slides in completely under the roof and the corresponding FOPS roof. The front guard is tensioned in the lower position using tension locks and locked in the upper position using a spring lock. The FOPS also has 4 screw-on points at the front and 2 screw-on points at the rear for mounting spotlights, which are additionally protected by the roof. The design is optimally adapted to the shape of the cabin. The retractable FOPS is mounted using only the cab’s existing screw points and therefore requires no adjustments. All individual parts are sandblasted, primed and powder-coated, which ensures an attractive appearance and corrosion protection. We also include detailed assembly instructions and a spare parts list with every FOPS delivered.

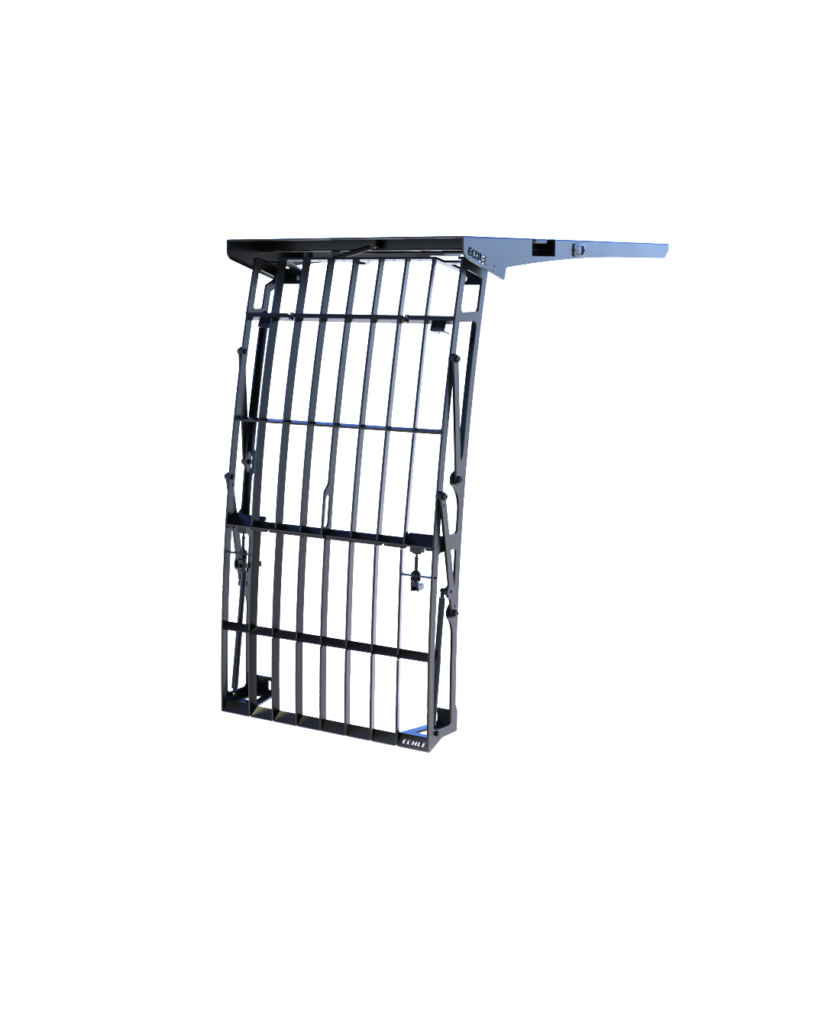

Folding FOPS

The deployable or folding FOPS from ECHLE meets all the necessary regulations (type examination in accordance with ISO 10262 category 2 for roof and front protection and applicable standards) to guarantee comprehensive protection for the cab and the machine operator. Conformity was verified by field tests in accordance with the applicable standards.

The folding cab guard generally consists of the FOPS roof and a front guard section that can be opened using gas springs to clean the windshield (see illustrations on the right). The FOPS is installed using only the existing screw points on the cabin and therefore does not require any welding work. The protective structure also has 4 screw-on points at the front and 2 screw-on points at the rear, which are used to mount headlights and are protected by the roof when attached. The design is specially adapted to the shape of the cab and therefore fits perfectly into the overall appearance of the machine. All individual parts are sandblasted, primed and texture powder-coated, which gives the grille an excellent appearance and the necessary corrosion protection. Each FOPS supplied also comes with detailed assembly instructions and a spare parts list.

For selected machine types, this FOPS variant is available as an “extra flat” version, which means that the overall height is just approx. 40 mm, so that the transport height is only slightly increased.

Frame-mounted FOPS

The frame-mounted FOPS is the heavy-duty version of the cab protection superstructure and also meets the safety requirements of ISO 10262 category 2. Thanks to the additional frame structure, which is attached to the uppercarriage frame and completely encloses the cab, this protective structure has proven its worth particularly in quarries and forestry.

The frame-mounted cab guard has a front protective grille that can be folded up towards the boom so that the windshield can still be reached manually. The canopy also has 4 lamp attachment points at the front and 2 lamp attachment points at the rear.

The option of integrating an automated splinter guard, which can be lowered or raised at the touch of a button using the specially designed drive system, offers particular added value.

Polycarbonate FOPS

The polycarbonate FOPS is the first of its kind. Developed to offer the machine operator maximum comfort and maximum safety at the same time, and all without additional steel struts in the field of vision. This protective structure is also type-tested in accordance with ISO 10262 category 2 for roof and front protection.

The front guard replaces the original windshield and is permanently attached to the cab. An additional, new wiper system is not necessary, as the protection can be optimally integrated into the cabin.

The roof also has a polycarbonate pane that can be opened as a hatch. This also creates an optimum view upwards with simultaneous accessibility of the original roof window for cleaning or maintenance purposes. Additional lights can be retrofitted at the additional mounting points on the roof, making the entire surrounding area even more visible.