Your construction machine as an individual project:

Undercarriage modification

Our undercarriage modifications at a glance:

or telescopic undercarriages are used to improve stability when working with long work equipment and heavy attachments.

To transport the machine, the chassis width can then be retracted to the width of the uppercarriage.

We carry out the following to facilitate work in constricted areas and to ensure easier transportation.

serve to improve stability when working at right angles to the undercarriage.

lead to an increase in stability when working alongside the undercarriage.

are attached to both sides of the drive. They prevent building rubble or steel parts from being pulled into the crawler track and thus protect the uppercarriage from damage.

are used for leveling surfaces and supporting the machine.

protect the electrical and hydraulic rotating union.

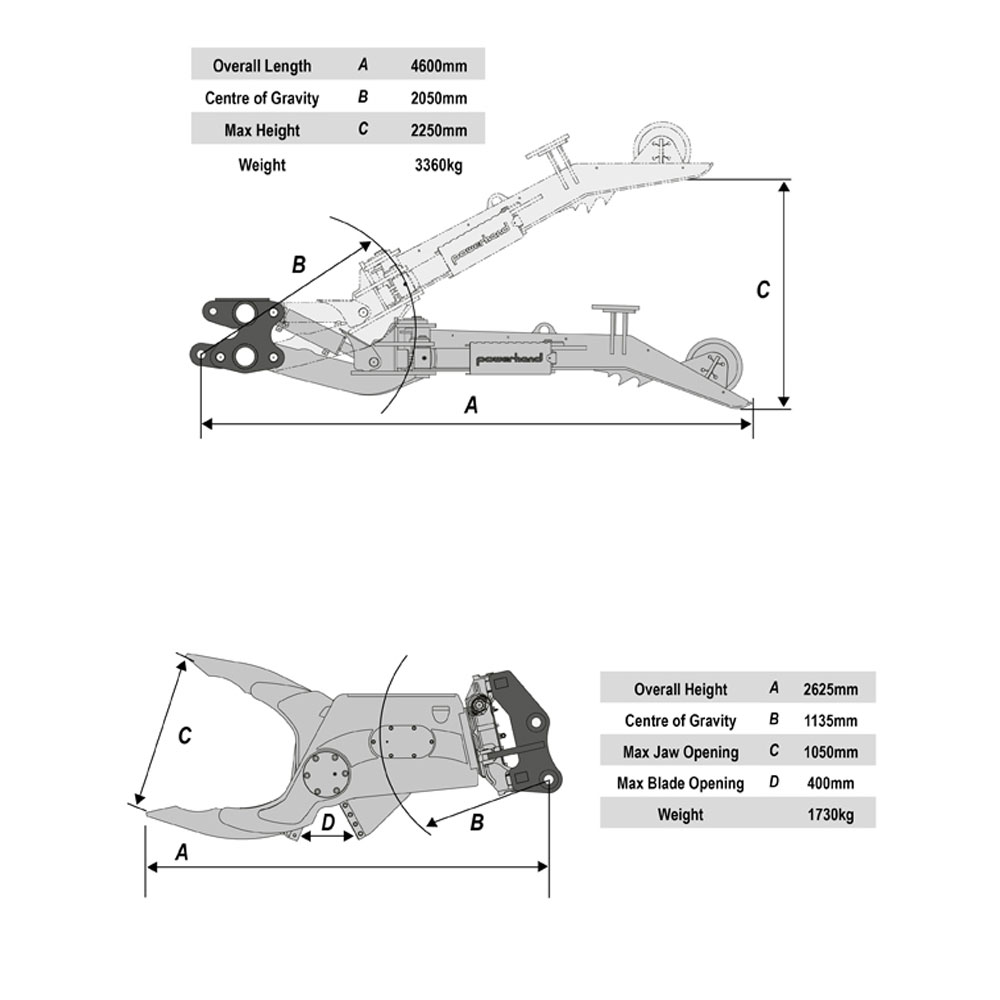

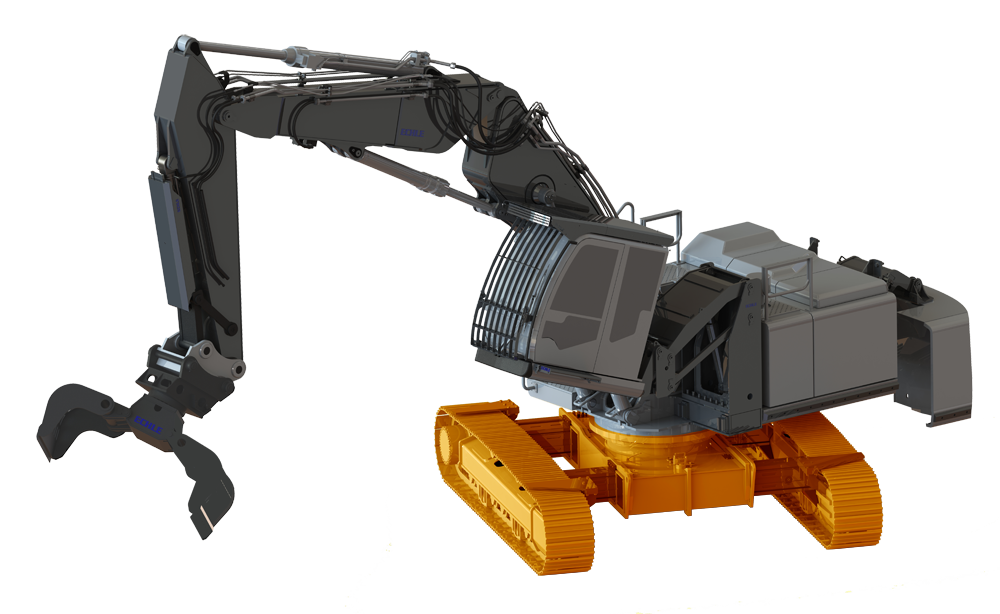

Vehicle recycling: We are the exclusive dealer of the Powerhand VRS, which enables you to get the maximum residual value from end-of-life vehicles.

Like a bird of prey dismantling its prey, the VRS holds the vehicle in place with its clamping legs. The valuable materials can thus be systematically removed from the less valuable vehicle body with the gripper.

The gripper has a slim tong shape that allows an unrestricted line of sight between the crane operator and the vehicle. This means that materials such as the copper wiring harness can be removed even from the tightest of spaces. Powerful hydraulic cylinders and a high-torque turning unit give the VRS the power to dismantle the vehicle effortlessly. The VRS consists of 100 % high-strength alloy steels to enable maximum performance. The system is suitable for mounting on standard machines between 16 and 22 tons.

Further information about Powerhand is available here.

Our undercarriage

modifications at a glance:

modifications at a glance:

or telescopic undercarriages are used to improve stability when working with long work equipment and heavy attachments.

To transport the machine, the chassis width can then be retracted to the width of the uppercarriage.

We carry out the following to facilitate work in constricted areas and to ensure easier transportation.

serve to improve stability when working at right angles to the undercarriage.

lead to an increase in stability when working alongside the undercarriage.

are attached to both sides of the drive. They prevent building rubble or steel parts from being pulled into the crawler track and thus protect the uppercarriage from damage.

are used for leveling surfaces and supporting the machine.

protect the electrical and hydraulic rotating union.

Vehicle recycling: We are the exclusive dealer of the Powerhand VRS, which enables you to get the maximum residual value from end-of-life vehicles.

Like a bird of prey dismantling its prey, the VRS holds the vehicle in place with its clamping legs. The valuable materials can thus be systematically removed from the less valuable vehicle body with the gripper.

The gripper has a slim tong shape that allows an unrestricted line of sight between the crane operator and the vehicle. This means that materials such as the copper wiring harness can be removed even from the tightest of spaces. Powerful hydraulic cylinders and a high-torque turning unit give the VRS the power to dismantle the vehicle effortlessly. The VRS consists of 100 % high-strength alloy steels to enable maximum performance. The system is suitable for mounting on standard machines between 16 and 22 tons.

Further information about Powerhand is available here.